ASML's dominance in EUV: key takeaways.

ASML is best known for wokring quietly in the background, while the likes of Nvidia, TSMC, Broadcom and Intel are at the front, making headlines, but many people seem surprised that a Dutch company makes highly complex machines that cost a lot to buy, which are very accurate in terms of manufacturing the most advanced chips in the world. Here is what they do, as I think many people need to understand clearly what this company does!

What is EUV technology?

EUV technology is like taking a very detailed image of a computer chip and transmitting it to a photo-sensitive material on a silicon wafer, in a very small area.

That’s it. But it’s not easy to make. Here is the process of making a chip by ASML’s machines:

Light

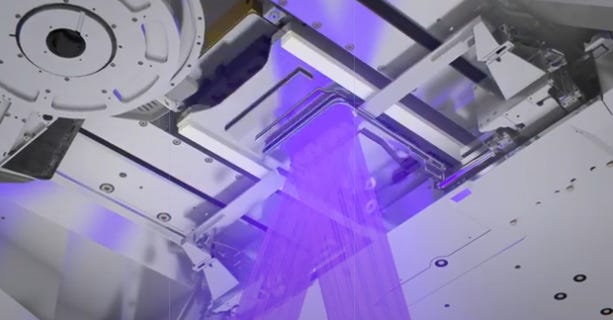

The patterns on the silicon need to be somehow transferred to the chip. Guess how they do it? A specific wavelength of light, barely above the wavelengths of X-rays, shoots out from a machine, which needs to produce tiny drops of tin, which are splattered by a laser, after which they are vaporised, to create the actual EUV light we are looking for. Sounds complicated? It’s because it is, and that machine repeats this process 50,000 times per second! And sometimes we have a problem limiting ourselves to 10 visits to the cookie tin! Guess what this machine would think! :)

The vacuum chamber

The space shown above contains the light source, as well as mirrors, which we’ll get into shortly. The light generated by the powerful light source we discussed earlier can be easily absorbed by almost anything, including air! That’s why ASML needed to create a perfect vacuum inside the machine. Space on Earth! Everything the light interacts with, from mirrors to the wafermust be in a complete vacuum.

The Reticle

Apart from mirrors in the chamber, we also need the actual blueprint that will be printed on the chip. We remember that EUV light can be absorbed by everything, except for this: a special multilayered mirror system, which is carefully aligned to match the design of the chip.

Mirrors

Light in traditional DUV (Deep Ultraviolet) uses lenses to focus light, but it can’t be used here, as it would absorb the light. That’s why huge and small multilayer mirrors are needed, which shrink the light by a factor of 4, and they need to be polished! So polished, that in fact, if you had Germany, its highest mountain would be 1mm above the surface, such a level of accuracy is needed.

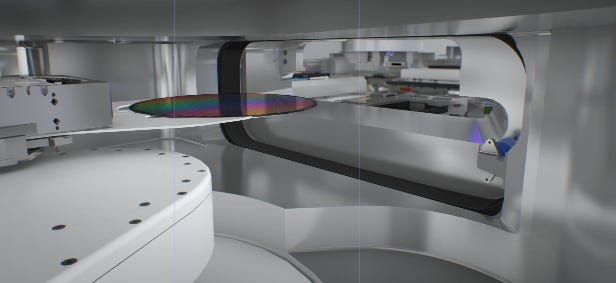

Wafer handler

Remember, we are in a vacuum! We can’t just open and close a door to get in or out. Remeber Interstellar? They also needed to enter their spaceship through an airlock when landing on other planets, otherwise, their spaceship would be empty of air. An airlock was needed here, and ASML made it. The wafers are moved by precision robot arms (accuracy of up to 25 µm) the equivalent of is dropping a mustard seed and making sure it lands within the width of a single strand of hair (even smaller than hair, but it’s the closest comparison!), and the difference in tempearteures is measured in the thousnads of a degree! For example, it can’t stay hotter than 20.002 degrees Celsius or colder than 19.998 degrees Celsius. Complex temperature management here!

Wafer Stage

The wafer is checked and adjusted 20,000 times per second during an exposure to EUV light.

As you can all see, it’s all a very complex process, one that is highly unlikely to be disrupted by other companies.

One might ask, why on earth aren't they being greedy and just raising prices indefinitely? Well, for starters, their rise in prices wouldn’t be beneficial for humanity. WHy? It’s because it would slow down our expansion of research, as fewer people could buy their machines, once they would reach truly ridiculous price tags, such as $1 billion. The second is that it isn’t necessary. They already have around 50% gross margin, and also, many governments would be interested in making them pay if they executed some of that pricing power, and so far, they are very well treated by governments, who seem to know of this company’s importance to their economy. The Dutch government has invested in ASML indirectly, through a multi-billion euro package known as "Project Beethoven."

This project is taking on infrastructure expansion, more affordable housing, curtailing unnecessary bureaucratic barriers, all of thin response to ASML considering expanding its operations abroad (which they do), to keep as many jobs as possible in the Netherlands. This is a great plus for the Dutch government, and I’m very happy as an ASML shareholder (0.3 shares currently).

A meme on ASML that will make you laugh:

This isn’t financial advice.